Clarke CMD10 Specifications

Browse online or download Specifications for Power drills Clarke CMD10. Clarke CMD10 Specifications User Manual

- Page / 24

- Table of contents

- BOOKMARKS

- OPERATING AND 1

- MAINTENANCE INSTRUCTIONS 1

- MILLING/DRILLING MACHINE 1

- Specifications 2

- CLARKE GUARANTEE 3

- Contents Page 3

- General Safety Precautions 4

- Electrical Connections 6

- Installation 7

- Parts Identification 8

- OPERATION 10

- B. Milling 12

- General Notes on Milling 13

- Cutting Speeds 13

- Maintenance 14

- Parts Diagram 15

- Parts List 18

- Accessories 20

- 3. Collet Set (MT3) 21

- 4. Quick Release Vice 21

- 6. Clamp Set 22

- 5. Indexable Carbide End Mill 22

Summary of Contents

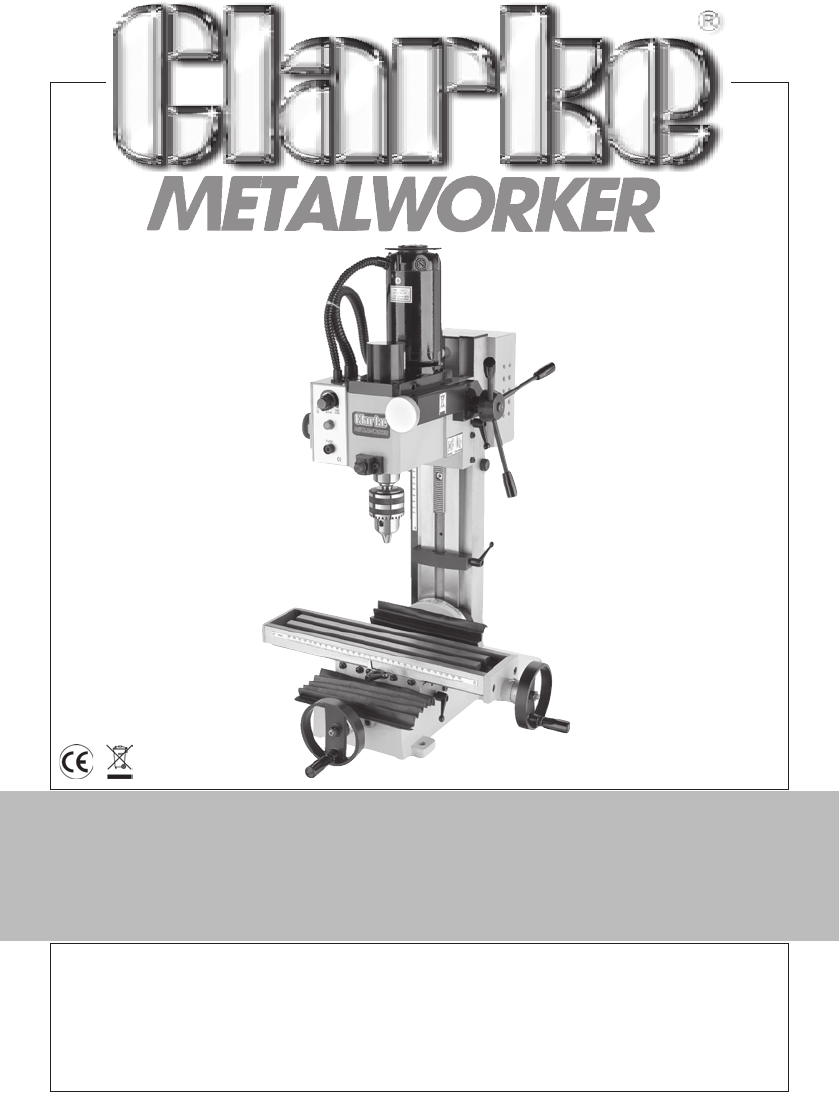

AH0209OPERATING ANDMAINTENANCE INSTRUCTIONSMODEL No. CMD300Part No. 7610860MILLING/DRILLING MACHINEMILLING/DRILLING MACHINE©CLICK HERE TO VIEW / BUY C

10OPERATIONWhen first using the machine, please usethe following procedure.1. Select LOW range, by moving theLever, adjacent to the EmergencyStop, ful

11In order to hold the spindle, insert the Tommy Bar into the hole in the side of the head sothat it locates in the hole in the spindle, see Fig. 5. H

12B. MillingVertical Milling is similar to drilling, except that instead of the workpiece being held stationary,it may be moved in 3 directions - a.

13knob whilst grasping the knurled rim of the scale and turning until the zero on the scale linesup with the pointer. Back off slightly and start the

14MaintenanceThe amount of maintenance depends on the amount of use the machine gets. However,it is important to carry out routine maintenance to prev

15Parts Diagram

16Parts Diagram

17Parts DiagramPARTS & SERVICE TEL: 020 8988 7400or e-mail as follows:PARTS: [email protected]: Service@clarkeinternat

18Item DescriptionQtyPart No Item DescriptionQtyPart No1 Base 1 SGCMD3000012 X-axis feed screw 1 SGCMD3000022-1 Key 4xl6 2 SGCMD3000034 Dial 2 SGCMD30

1985 Sleeve 1 SGCMD30008586 Pin 3xl2 I SGCMD30008687 Pin 3xl2 2 SGCMD30008788 Adjustable union 1 SGCMD30008889 Bracket 1 SGCMD30008990 Screw M5x25 1 S

2Model : ... CMD300Part No : ...

201. Mill Chuck SetA set comprising 7 collets, a chuck and‘C’spanner.Collet sizes:Part Number: 76108661. Insert the shank of the chuck into the Mill

213. Collet Set (MT3)Part Number: 7610864A set of 7 Collets for use with the HSS EndMills:Insert the appropriate Collet into thespindle.Insert the dra

226. Clamp SetPart Number: 76108725. Indexable Carbide End MillPart Number: 7910870An example of how the clamp set may be used:Select the appropriate

23

3Please read these instructions carefully before using this machineThank you for purchasing this CLARKE Milling/Drilling Machine, designed for drillin

4-5- General Safety PrecautionsWARNING: As with all machinery, there are certain hazards involved with their operationand use. Exercising respect and

514. ALWAYS wear proper apparel. Loose clothing or jewellerymay get caught in moving parts. Wear protective haircovering to contain long hair.15. AL

6This machine must be wired up in accordance with the following colour code:BLUE - NEUTRALBROWN - LIVEGREEN/YELLOW - EARTH• Connect the BLUE coloured

7InstallationIMPORTANT: Careful consideration is required when choosing the location for themachine, with regard to table movement, Mill/Drill Head mo

8Parts IdentificationFIG-AFIG-BFIG-C

91. Remove all polystyrene packaging material, then, with assistance lift the machine onto a workbench. DO NOT attempt to do this single handedly.2. U

More documents for Power drills Clarke CMD10

(12 pages)

(12 pages)

Comments to this Manuals